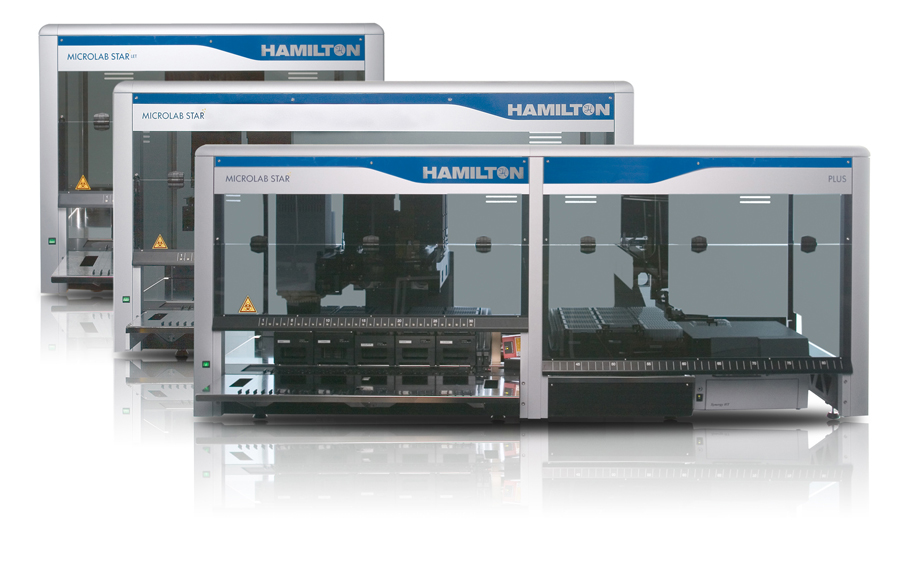

Microlab STAR Line

Artificial Intelligence

The Microlab STAR Line of workstations uses air displacement pipetting and the unique CO-RE system for forceless tip pickup and ejection. These unrivaled features maximize sample care and integrity. This technology is applied to independent pipetting channels and multiprobe heads; simply switch on your system and start running your method.

More Information

Invest in a Safe Future

Due to the modular design, changes and upgrades to existing configurations are easy with STAR instruments. As your projects change, your STAR workstation can also evolve to meet new challenges. Most upgrades can be performed in your lab within one or two days to minimize downtime.

- Automated intelligence with Hamilton’s air-based advanced pipetting features

- Reduced risk of contamination for critical assays due to the combination with disposable tips

- Less maintenance required due to no system liquid, diluters, valves or tubing

- No dilution effect of samples

Would you like to get started in automation with a benchtop workstation, but want the option to expand your system if needed? The STARlet can be extended to a STARplus with an extension module, more than doubling deck capacity.

The scalability of STAR Line instruments means that the widest possible range of throughputs and budgets can be accommodated: additional pipetting channels, a CO-RE 96, 384 Probe Head or an iSWAP plate handling arm can be fitted to existing configurations.

STAR Line instruments excel in automating multiple applications for both the biological and analytical sciences. Thousands of STAR Line workstations have been installed around the world to automate a wide range of applications. They offer the flexibility and modularity you need to create the perfect automated solution for your laboratory. For specific demands, the Hamilton Application Engineering (APE) group is available to design everything from custom racks to complex system integrations.

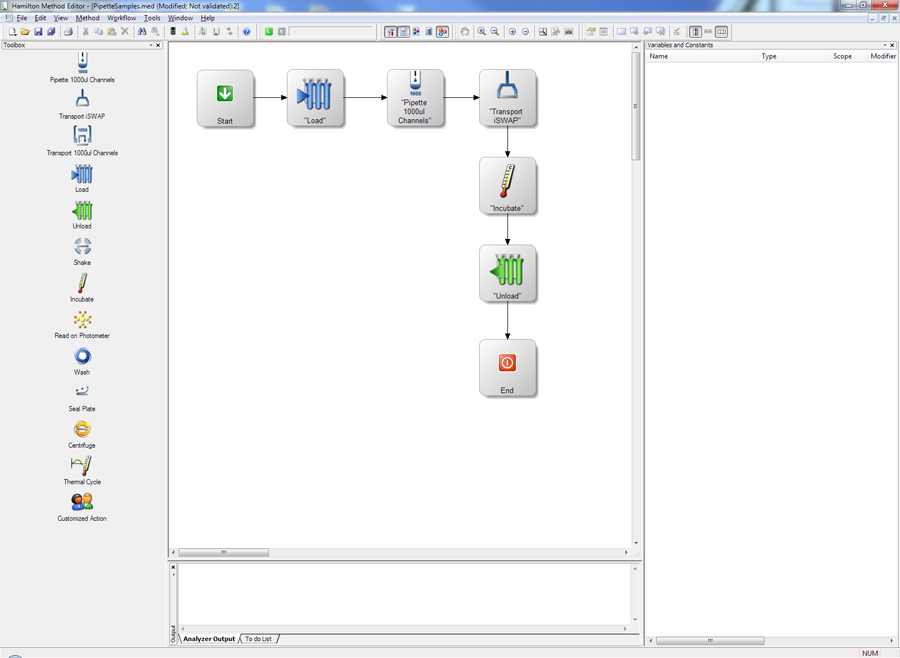

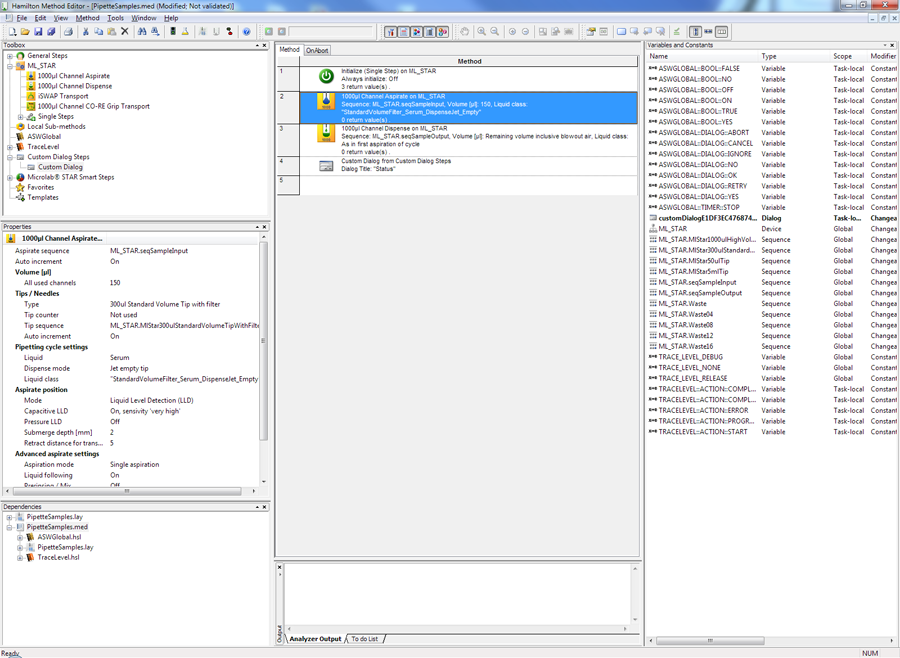

VENUS: powerful software for a powerful workstationThe system’s flexible hardware is reflected by VENUS software, which provides several programming levels to efficiently define your applications. VENUS offers simple or complex programming, without limiting your imagination or compromising your requirements. Additional software packages, such as the Dynamic Scheduler (for optimized resource use), the TADM feature (for full traceability of the pipetting workflow), the DataBasePlus option (to use remote tracking servers) and the Dynamic Liquid Classification plugin (for automatic liquid class selection), make VENUS even more powerful.

|  |

| |

|

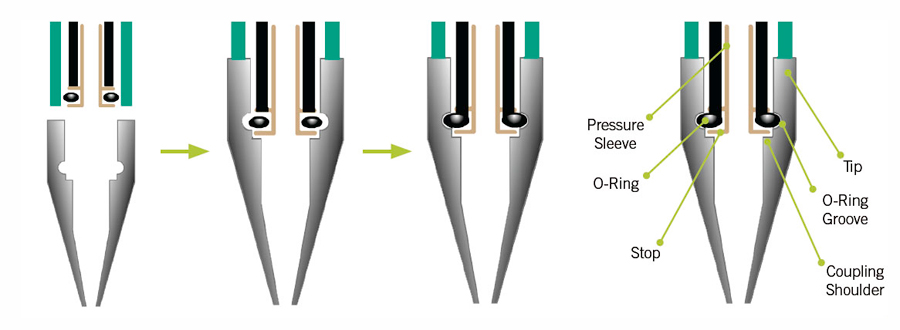

Compressed O-Ring Expansion (CO-RE)

Many of today’s applications require precision in tip attachment and positioning. To accomplish this, Hamilton utilizes proprietary Compressed O-Ring Expansion (CORE) technology. CO-RE technology attaches disposable tips using a highly robust lock-and-key style mechanism. This enables a positional precision of + 0.1mm on all axes. The system requires virtually no vertical force for tip attachment or ejection, thus eliminating mechanical stress and minimizing the production of aerosols. Reduced stress also improves overall system reliability and throughput.

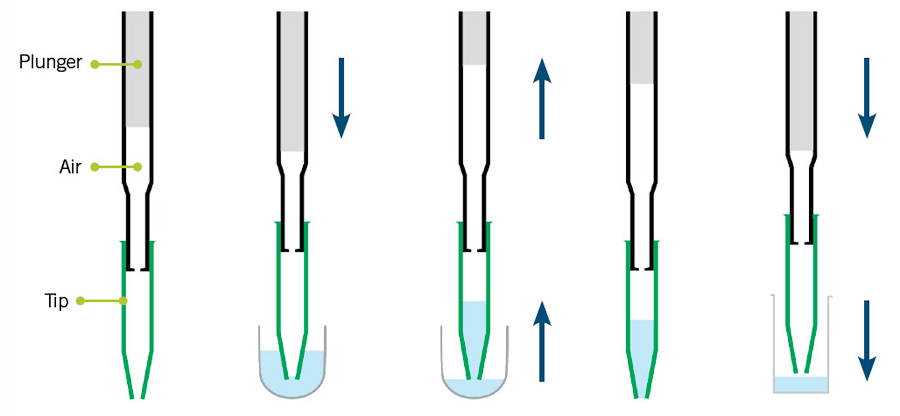

Air Displacement Pipetting

The Hamilton STAR Line utilizes proven air displacement pipetting, similar to high precision handheld electronic pipettors. Benefits of this technology include:

- Reduced risk of contamination or sample dilution (no system fluid)

- High pipetting accuracy and precision from sub-microlitre to large (>1 mL) volumes

- Increased robustness and easier maintenance owing to lack of system liquids, diluters, valves or complicated tubing

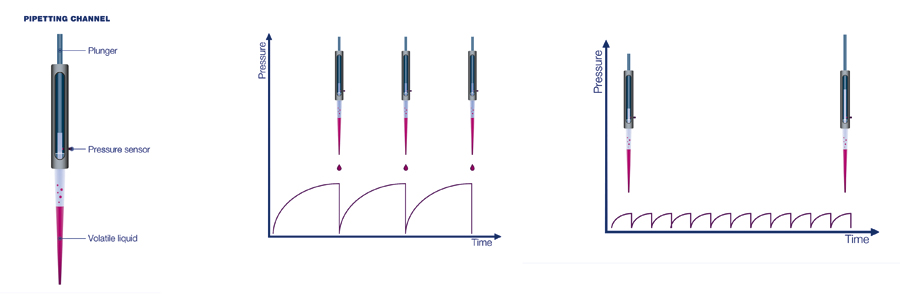

Anti-Droplet Control (ADC)

This technology serves to compensate in real time for pressure changes in the liquid channels caused by high vapor pressure of volatile solvents. Upon activation, ADC prevents inadvertent dripping from the channels, reducing the risk of contaminating the deck. ADC detects and reacts on pressure changes in the channels that are caused by the high vapor pressure of volatile solvents in real time. This feature is available with single pipetting channels.

Monitored Air Displacement (MAD)

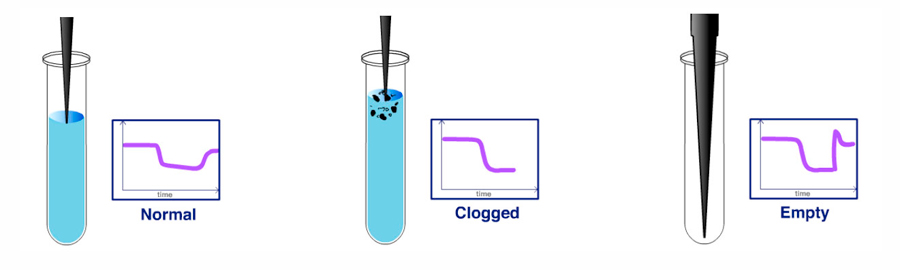

By monitoring the air-based pipetting action, the platform can detect clots or empty wells during the aspiration step in real time. It can also be used to pipette highly volatile solvents. With MAD your pipetting robot gives you a feedback on the real-time tracking of the aspiration performance.

Therefore MAD delivers a confirmation of the successful aspiration. Monitored Air Displacement eliminates uncertainty in automated assays by providing reliable, consistent walk-away automation.

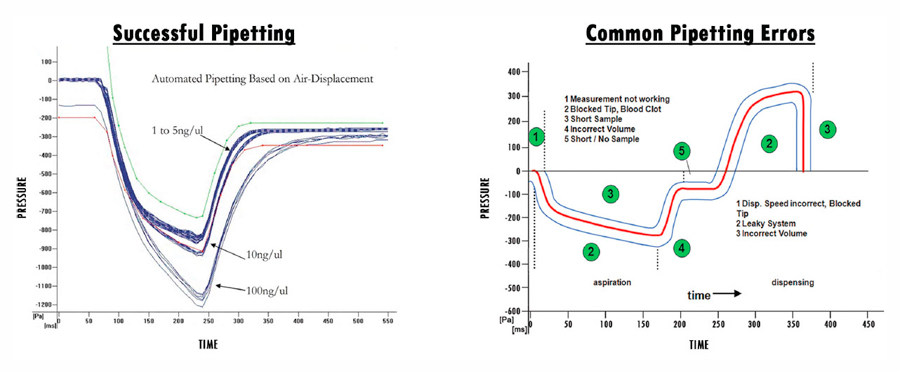

Total Aspiration and Dispense Monitoring (TADM)

During crucial sample transfers (e.g. in vitro Diagnostics or DNA Forensics), parameters may be set to monitor, in real time, both the aspiration and dispense steps. TADM verifies with a traceable digital audit trail that a sample has been successfully transferred.

Liquid Level Detection (LLD)

The Hamilton STAR uses LLD technology to determine liquid levels in tubes and plates located on the pipetting deck. There are two modes of LLD: capacitative LLD (c-LLD), used to detect most types of liquids in most types of vessels; and pressure-based LLD (p-LLD), which can detect virtually all fluid types, including foaming liquids and non-conductive organic solvents. cLLD is available (MPH channels A1, B2, G11 & H12); pLLD is available. For even greater confidence in COMPRESSED O-RING EXPANSION (CO-RE) LLD, a dual mode LLD approach may be used.

STAR Line Functional & Performance Specifications

Dimensions | ||||

| Length: | Width: | Width with Autoload: | Height: | |

| Microlab STARlet | 44.3 in (112.4 cm) | 31.3 in (79.5 cm) | 39.6 in (100.6 cm) | 35.6 in (90.3 cm) |

| Microlab STAR | 65.5 in (166.4 cm) | 31.3 in (79.5 cm) | 39.6 in (100.6 cm) | 35.6 in (90.3 cm) |

| Microlab STARplus | 85.0 in (216.0 cm) | 31.3 in (79.5 cm) | 39.6 in (100.6 cm) | 35.6 in (90.3 cm) |

Deck Capacity | ||||

| Microlab STARlet | 30 tracks (T) allow combinations of: maximum of 30 tube carriers (1 T) holding 24 or 32 tubes per carrier maximum of 5 carriers (6 T) holding 5 tip racks or 5 plate positions per carrier | |||

| Microlab STAR | 54 tracks (T) allow combinations of: maximum of: maximum of 54 tube carriers (1 T) holding 24 or 32 tubes per carrier maximum of 9 carriers (6 T) holding 5 tip racks or 5 plate positions per carrier | |||

| Microlab STARplus | 71 tracks (T) allow combinations of: maximum of: maximum of 71 tube carriers (1 T) holding 24 or 32 tubes per carrier maximum of 11 carriers (6 T) holding 5 tip racks or 5 plate positions per carrier | |||

Pipetting specifications * | ||||

| Pipetting specifications for disposable tips individual 1000µl-channels | Disposable tip size 10µl 10µl 10µl 10µl 50µl 50µl 50µl 50µl 300µl 300µl 300µl 1000µl 1000µl 1000µl | Volume 0.5µl 1µl 5µl 10µl 0.5µl 1µl 5µl 50µl 10µl 50µl 200µl 10µl 100µl 1000µl | Trueness |R| (%) 10.00% 5.00% 2.50% 1.50% 10.00% 5.00% 2.50% 2.00% 5.00% 2.00% 1.00% 7.50% 2.00% 1.00% | Precision CV (%) 6.00% 4.00% 1.50% 1% 6.00% 4.00% 1.50% 0.75% 2.00% 0.75% 0.75% 3.50% 0.75% 0.75% |

| Pipetting specifications for needles individual 1000µl-channels | Needle size 10µl 10µl 10µl 300µl 300µl 300µl 1000µl 1000µl 1000µl | Volume 1µl 5µl 10µl 5µl 50µl 200µl 50µl 100µl 1000µl | Trueness |R| (%) 5.00% 2.50% 1.50% 8.00% 2.00% 1.00% 5.00% 3.00% 2.00% | Precision CV (%) 8.00% 2.00% 1.00% 8.00% 2.00% 1.00% 3.00% 2.00% 1.00% |

| Pipetting specifications for 5ml disposable tips individual 5ml-channels | Disposable tip size 5ml 5ml 5ml 5ml | Volume 50µl 500µl 1000µl 5000µl | Trueness|R| (%) 5.00% 2.00% 1.50% 2.00% | Precision CV (%) 2.50% 1.50% 1.00% 1.50% |

| Pipetting specifications for disposable tips 1000µl CORE 96 Probe Head | Disposable tip size 10µl 10µl 10µl 50µl 50µl 50µl 300µl 300µl 300µl 1000µl 1000µl 1000µl | Volume 1µl 5µl 10µl 1µl 5µl 50µl 10µl 50µl 300µl 10µl 100µl 1000µl | Trueness|R| (%) 5.00% 2.50% 1.50% 5.00% 2.50% 1.50% 3.00% 1.50% 1.00% 7.50% 2.00% 1.00% | Precision CV (%) 5.00% 2.00% 1.50% 5.00% 2.00% 1.00% 2.00% 1.00% 1.00% 3.50% 1.00% 1.00% |

| Pipetting specifications for disposable tips 50µl CORE 384 Probe Head | Disposable tip size 50µl 50µl 50µl 50µl 50µl 50µl 50µl 50µl 50µl | Volume Surface: 0.1µl Surface: 0.5µl Surface: 1µl Jet: 1µl Surface: 5µl Jet: 5µl Surface: 10µl Jet: 10µl Surface/Jet: 50µl | Precision CV (%) 8.00% 6.00% 3.50% 15.00% 3.00% 4.00% 2.00% 3.00% 2.00% | |

| Using the 50µl CORE 384 Probe Head | Disposable tip size 300µl Rocket 300µl Rocket 300µl Rocket 300µl Rocket 300µl Rocket | Volume 2µl 5µl 10µl 100µl 300µl | Precision CV (%) 4.00% 2.00% 2.00% 2.00% 2.00% | |

| Liquid Level Detection | Individual Channels: Capacitive liquid level detection (cLLD) and pressure (pLLD) on aspiration, cLLD on dispense, minimum volume 10 μL, depending on container type 96- and 384-Probe Head: Capacitive liquid level detection (cLLD) | |||

| Labware | All SBS standard plate types up to 1536 wells and most commercially available tube types | |||

| Carrier | For all standard labware formats and according to customer requirements | |||

| Accessories | CO-RE Gripper for economical on-deck transports, iSWAP Robotic Hand for transports below or off-deck, Barcode Reader, Temperature Controlled Carriers, Needle Wash Station with parallel Needle Washing, Vacuum System, CO-RE Lid Suck Tool for Petridish Lid handling, EasyPick Camera and Accessories for economical Colony picking, Tube Gripper, Tip-Feeder | |||

| Operating Data | Maximum power consumption: | 600 VA or 1000 VA (depending on configuration) | ||

| Voltage: | 115 V~/230V~ | |||

| Frequency: | 50 / 60 Hz ± 5% | |||

| Delayed action fuse: | 115 V~: 6.3 A, 230 V~: 3.15 A | |||

| Operating temperature range: | 15°C - 35°C (relative humidity 30% - 85% with no condensation) | |||

*Test criteria available upon request | ||||

Configure your pipetting platform

Choose from one of the platform sizes: STARlet, STAR or STARplus,

and select pipetting channels, multiprobe heads and other tools.

- Up to 16 independent 1000 µL pipetting channels

- Up to 8 independent 5 mL pipetting channels

- CO-RE 96-Probe Head 1000 µL (with or without TADM)

- CO-RE 384-Probe Head 50 µL

In addition you select: Platehandler iSWAP and CO-RE Gripper,Tube handler,Decapper and Imaging system (camera channel).

Pipetting Channels

Years of experience and development in liquid handling have enabled Hamilton to create a highly precise and robust tool: the 1000 µL pipetting channel, which can pipette volumes as low as 0.5 µL and as high as 1000 µL. Different disposable tip sizes that are specifically shaped enable the highest pipetting precision. Due to the possibility of unique asymmetric spreading, the system can reach every position on the deck and supports complex pipetting patterns, thus enabling quicker pipetting. The 5 mL channel for higher volumes uses the same precise technology to pipette volumes from 50 µL to 5 mL. These high-volume pipetting channels are also asymmetrically spreadable.

Multiprobe heads

To speed monitored processes that require highly parallel liquid handling, Hamilton has developed the CO-RE 96-Probe Head with a volume range of 1 to 1000 µL, and the CO-RE 384-Probe Head with a volume range of 0.1 to 50 µL. Both can be added to all Microlab STAR Line instruments with multiprobe capability and combined with other modules on the flexible STAR platform. Combining multiple functions on a single STAR Line instrument avoids time-consuming transfers between different liquid handling systems, saving both laboratory space and costs.

Modularity and scalability

Due to the modular design, changes and upgrades to existing configurations are easy with STAR Line instruments. As your projects change, your STAR Line workstation can also evolve to meet new challenges. Most upgrades can be performed in your lab within 1-2 days to minimize the instrument’s downtime. The STARlet can be extended to a STARplus with an extension module, thereby more than doubling deck capacity. The scalability of STAR Line instruments means that the widest possible range of throughputs and budgets can be accommodated: additional pipetting channels, a CO-RE 96, 384 Probe Head or an iSWAP can be fitted to existing configurations.

Upgrade your robot

In addition to the wide range of functional deck equipment such as the vacuum station, heaters and shakers, STAR Line systems can be upgraded with:

- Up to 16 x 1000μl channels

- Up to 8 x 5ml channels

- Multiprobe heads

- Labware handling tools

- Imaging channel

- Platform upgrade

Unlimited flexibility, free choice of desired labware, quick and simple customization

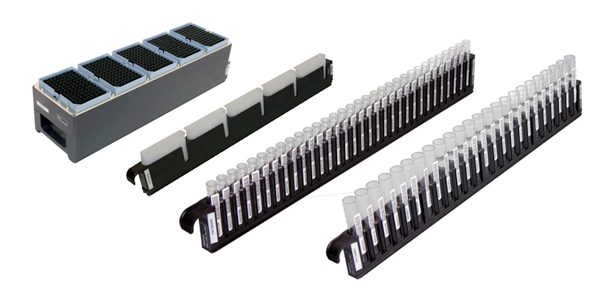

Carrier Concept

For flexible placing of your labware Hamilton has developed carriers for the STAR Line instruments. These carriers hold your labware in place on the deck. The carriers can be loaded manually or automatically.

Multiflex Concept

Select from a broad range of Multiflex modules to configure your desired carrier and deck layout. A base carrier plate enables flexible placing of these modules for all common labware: Microtiter plates, deep-well plates, 96-or 384-well PCR plates, plate-, petri dish- or tip-stackers, tube holders, reagent troughs, tilt modules, heating and cooling modules and many more options.

The layout of Multiflex carriers can be changed according to your needs. From shakers to heating or cooling modules, tube or plate modules, Multiflex carriers can be designed to exactly fit the application.

CONTACT US

CONTACT US